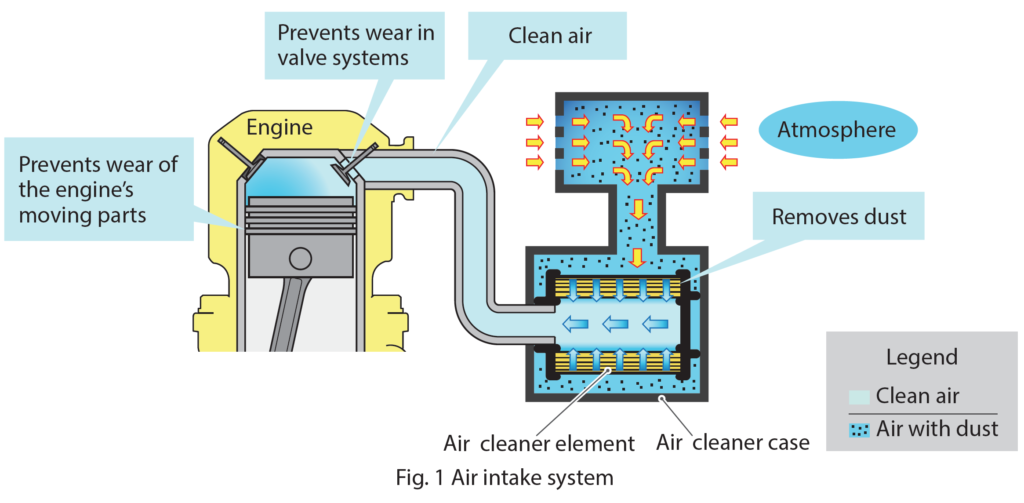

The function of the air cleaner element is to remove dust contained in the intake air so as to supply clean air to the engine, and protect the moving parts in the engine from wear.

How foreign matter in air affects your engine

Causes

Effects

Engine Condition

- Dust

- Carbon

- Excessive wear on the engine’s moving parts

- Excessive wear in valve systems

- Excessive engine oil consumption

- Loss of output

- Bad fuel economy

- Emission problems (incomplete combustion)

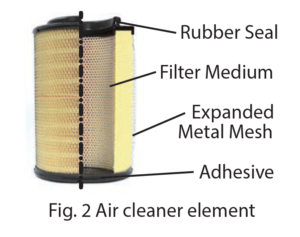

2. Construction

Rubber Seal

This seal ensures that outside air is not sent directly into the engine.

Filter medium

This captures dust in the air.

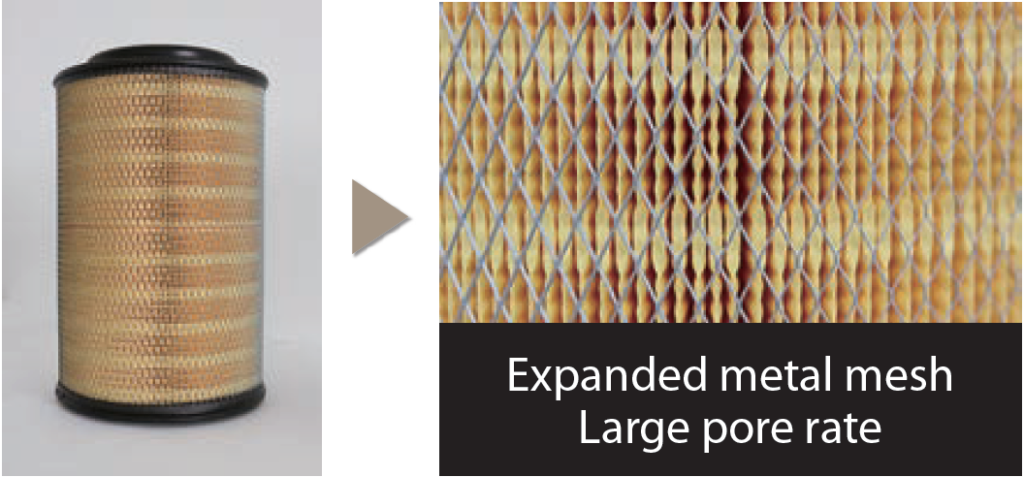

Expanded metal mesh

This supports the filter medium.

Adhesive

This holds the element and plate together.

3. Types of elements

1) Types of elements

Air cleaner elements come in two types: dry and wet, depending on how they capture dust. Dry types come in two types: chrysanthemum shape and honeycomb, depending on how their filter medium is folded.

Type

Cleaning efficiency

Filter medium

Applications (and vehicle types)

Type of filter medium fold

Mode of dust capturing

Dry

Approx. 99~ 99.9%

Primarily unpaved roads

Dump trucks, etc.

Chrysanthemum shape

Honeycomb

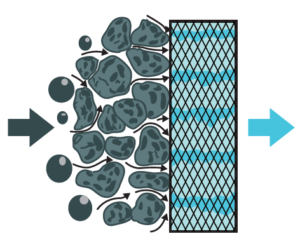

Dust is captured on the surface of the filter medium.

Wet

Approx. 95~ 99%

Primarily paved roads

Cargo trucks, buses, etc.

Chrysanthemum shape

The filter medium in this element has been soaked with oil. The oil soaks into the dust caught on the surface of the filter medium to form a filtering layer. This process is repeated over and over to constantly form new filtering layers.

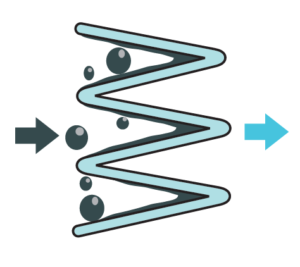

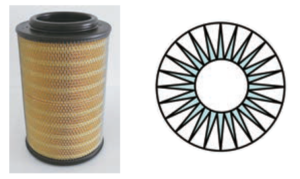

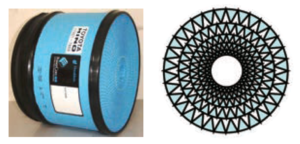

2) Types of filter medium folds: Chrysanthemum shape and honeycomb

Chrysanthemum shape

This is the common type of fold used in filters.

Honeycomb

Compared to chrysanthemum shape folds, this type of fold provides about twice the filtering area for a given volume. Also, because it has 20% less airflow resistance, this is used to make long-lasting elements that are small and yet provide large filtering areas.

<Remarks>

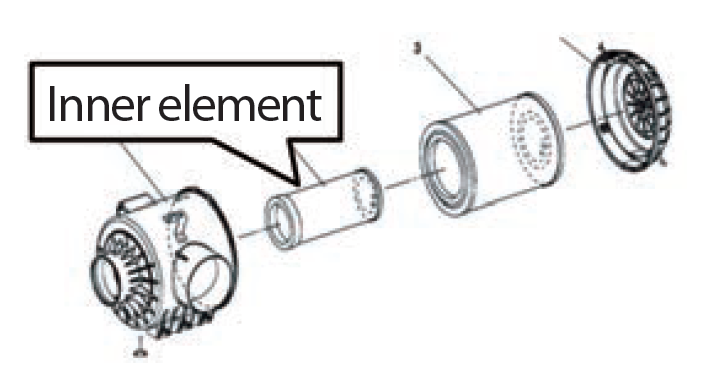

Inner element: Some air cleaner elements have an inner element. This keeps dust from entering the engine when the outer element is being cleaned or replaced. The inner element is designed solely to keep dust from entering and does not allow dust to pass through.

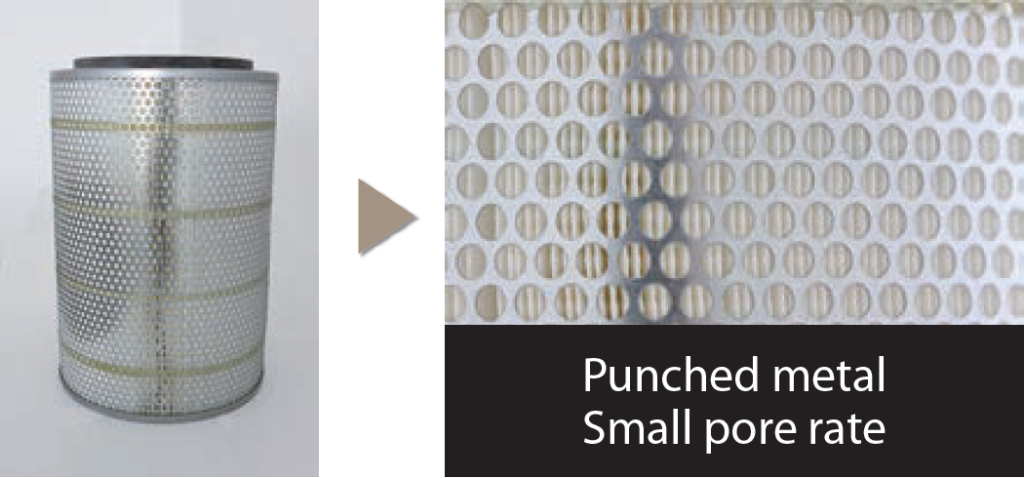

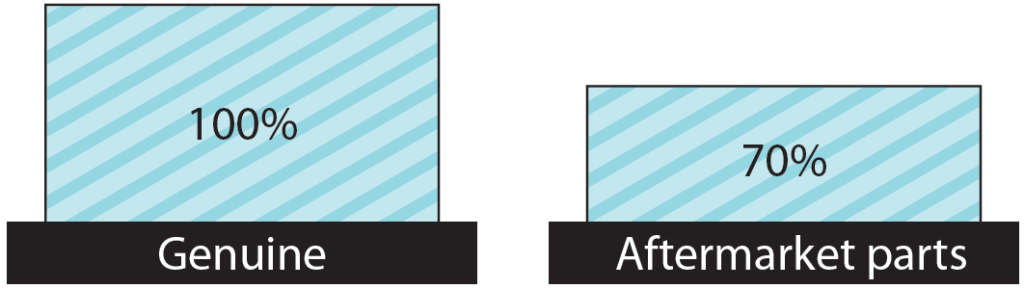

4. Differences between genuine and aftermarket parts

1) Performance

The filter media in genuine parts are held in place with an expanded metal mesh, providing a pore rate of 80%. This produces low airflow resistance, which in turn results in smaller loss of output, and better fuel economy. In some aftermarket parts, the filter medium is held in place with punched metal. This can reduce the pore rate of the filter medium to 40%, which in turn increases airflow resistance, resulting in greater loss of output.

Genuine

Aftermarket parts

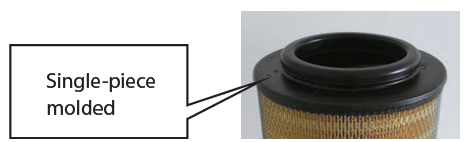

2) Quality

Because the ends of the filter medium in genuine parts are made of single-piece molded plastic and glued in place with adhesive, there is no concern of dust leakage. Although the separate parts in aftermarket parts are glued together by adhesive, there can be inconsistencies in adhesion which can lead to dust leakage.

Genuine

Aftermarket parts

3) Life Cycle

(1) Genuine parts provide more folds and sufficient filtering areas. Some aftermarket parts have smaller filtering areas and shorter life cycles.

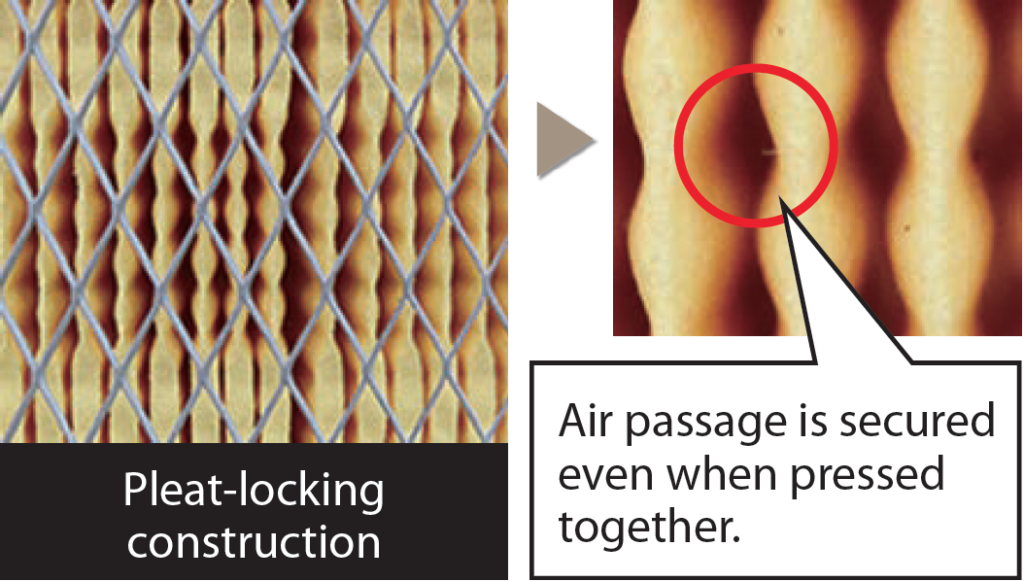

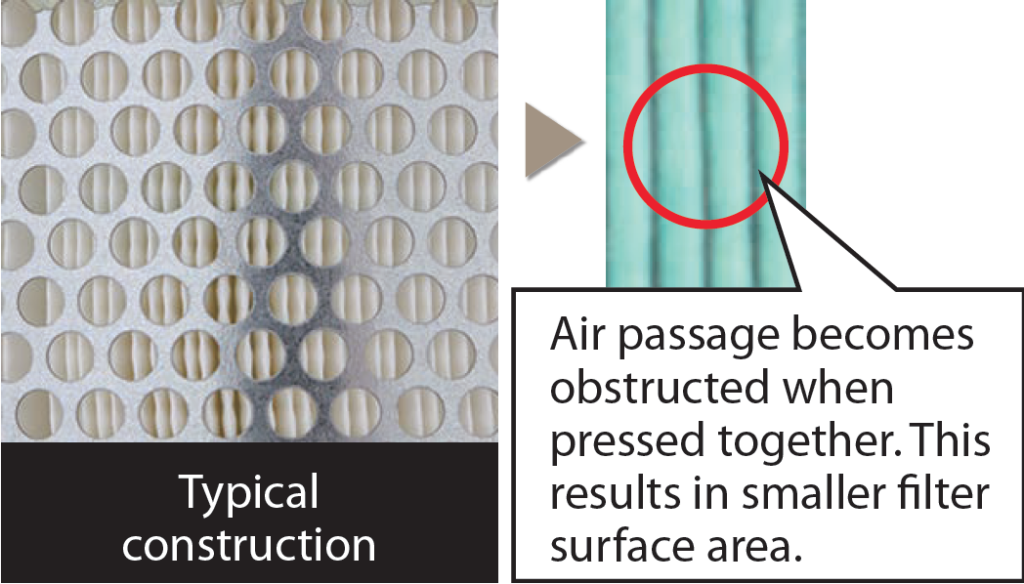

(2) Genuine filters feature a pleat-locking construction to properly maintain the spaces between filter medium surfaces in order to maintain its effective surface area. Filter media in some aftermarket parts can become stuck to each other, which can obstruct airflow, reduce the effective surface area, and shorten the filter’s life cycle.

Genuine

Aftermarket parts

The performance data of aftermarket parts shown above were obtained from a limited sampling of parts and do not represent the performance of all aftermarket parts.

5. The importance of maintenance

Continuing to use a dirty air cleaner element instead of replacing it may impair your engine’s performance or fuel economy, so you must clean or replace your air cleaner periodically. In a worst case scenario, the filter medium can rupture, allowing dust to enter the engine, which can cause engine breakdowns.

Loss of engine power

Fuel economy drops