The oil filter removes carbon and other impurities from the engine oil to maintain performance and protects the engine from damage due to abrasion in its moving parts.

Possible engine damage due to oil impurities:

Causes

- Dust

- Oxidation products (e.g. rust)

- Metal flakes

Effects

- Abnormal abrasion of the engine’s moving parts

- Oil deterioration

- Oil loss

Engine condition

- Drop in engine output (horsepower)

- Increased fuel consumption

- Increased oil consumption

- Shortened engine life

2. Construction

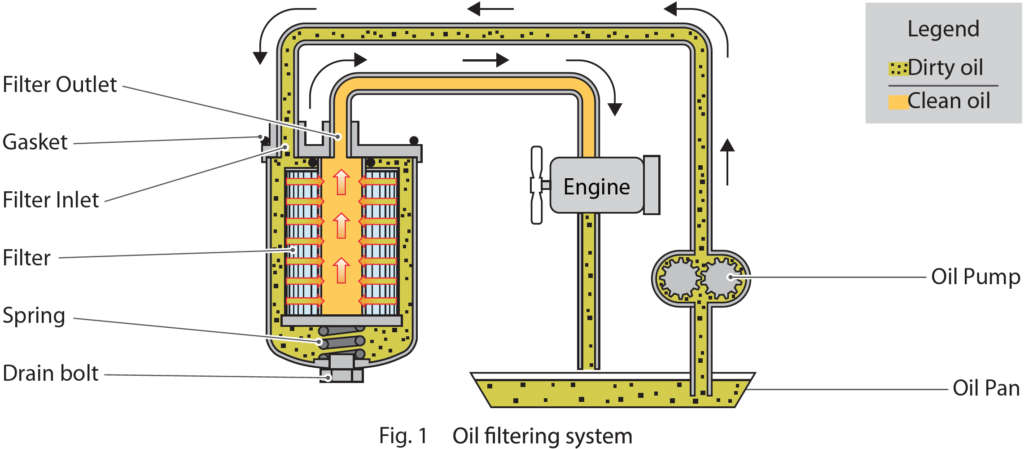

The oil pump sends oil to the oil filter via the filter inlet. Once filtered, the oil is pumped back to the moving parts of the engine. (See Fig. 1)

- Filter – Removes dust, oxidation products and metal flakes from the engine oil

- Gasket – Seasl to prevent oil from leaking into the filter casing at the joint area

- Spring – Secures the filter to the filter case

- Drain bolt – Removal enables oil drainage prior to filter replacement

3. Filter types

1) There are two major types of oil filters classified by the method of replacement:

Spin-on Filter

The filter medium is contained in a metal case that can be wholly removed and replaced by removing a single attachment screw in the bottom, making it easy for mechanics to work with.

Cartridge Filter

The filter medium is not contained in a metal casing, enabling the replacement of just the filter medium, making it more environmentally friendly due to waste reduction.

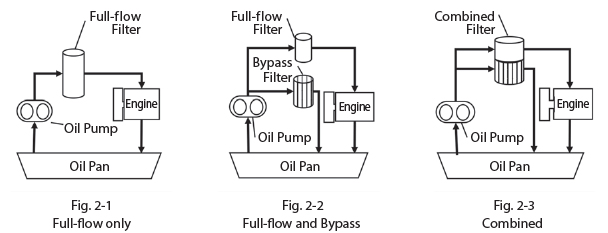

2) Within these two major filter types, there are three mechanisms for engine oil flow:

Full-flow Filter

Filters all engine oil flowing from the oil pump, sending it directly back to the moving parts of the engine. Capable of high-volume flow over a small filtering area.

(See Fig. 2-1)

Bypass Filter

Some engine oil flowing from the oil pump is returned to the oil pan without being sent to the moving parts of the engine. Used in parallel with a full-flow filter to increase filtration effciency. (See Fig. 2-2)

Combined Filter

Has both a full-flow and a bypass filter in a single casing. Engine oil flowing from the oil pump flows separately into the full-flow filter and the bypass filter. (See Fig. 2-3)

Engine oil flow

4. Differences between genuine and aftermarket parts

1) Performance

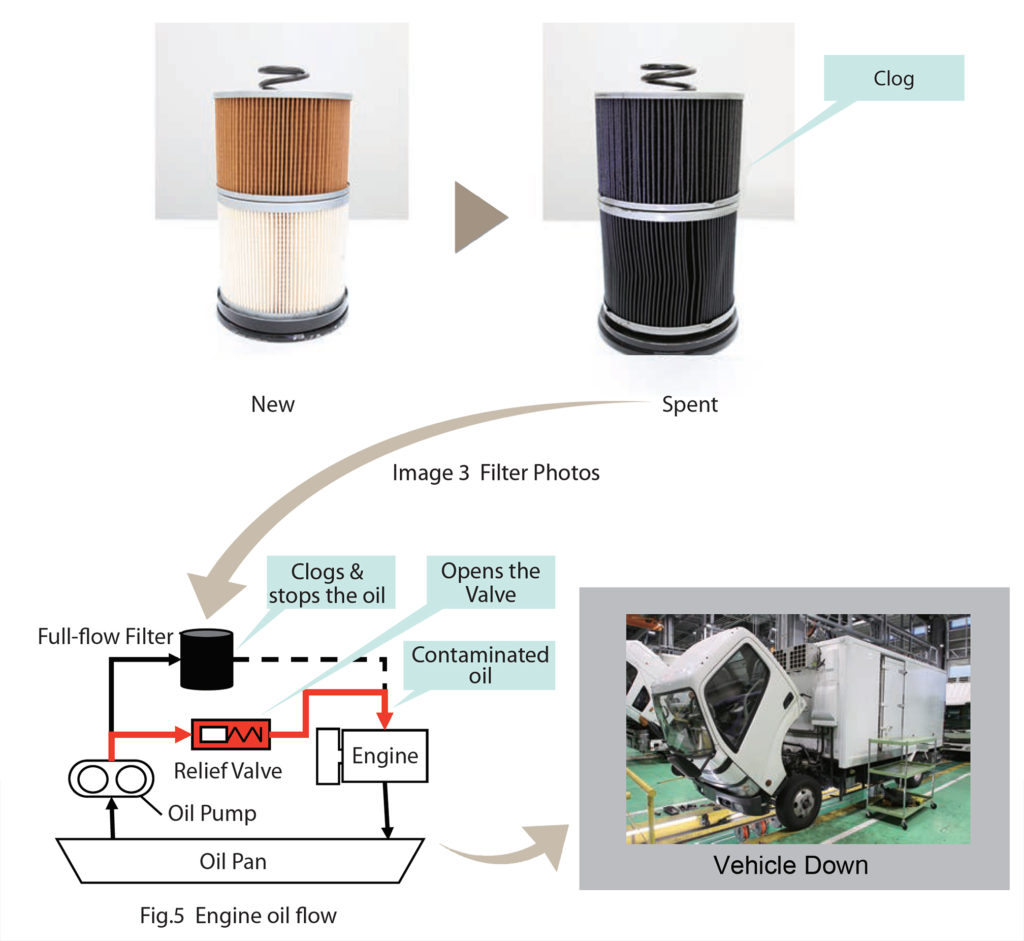

The filter paper of genuine parts has multiple layers of differing roughness and fiber density. This combination of special fibers creates fine passages that ensure maximum impurity removal. By comparison, the performance of aftermarket parts with only one layer of rough fiber may be insufficient to ensure maximum performance. (See Image 1)

2) Quality

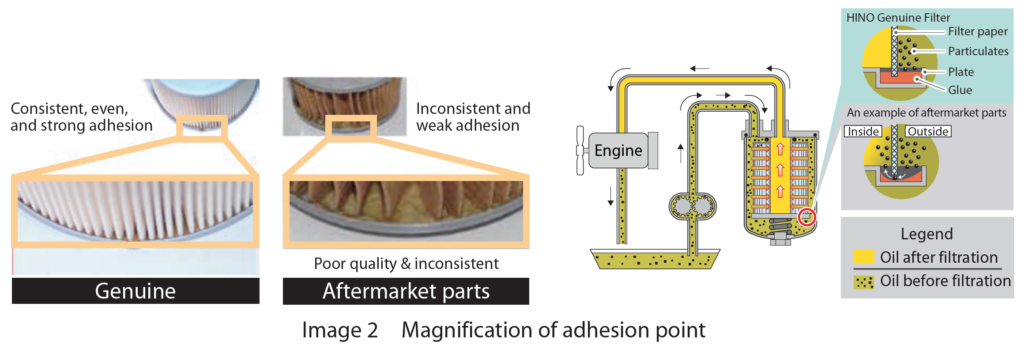

The filter paper in genuine parts is bonded to the end plate using proprietary adhesive and assembly technology, ensuring a leak-proof connection. This means engine oil does not leak at the adhesion point. By comparison, because the paper in some aftermarket parts may be imperfectly bonded, they may fail to catch some impurities. (See Image 2)

3) Life Cycle

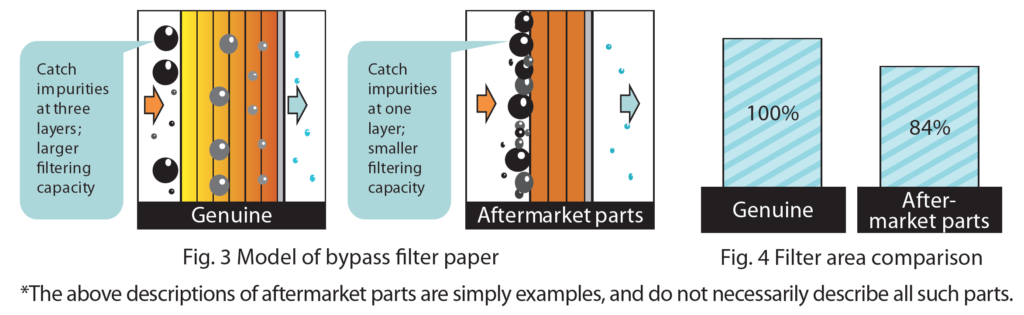

Genuine bypass filters have three layers made of special paper that gives them high filtering performance while remaining difficult to clog. (See Fig. 3) The filtering area is also designed to ensure optimized filtration distance. (See Fig. 4) Some aftermarket parts may have a reduced life since they have only one filter layer and a smaller filtering area.

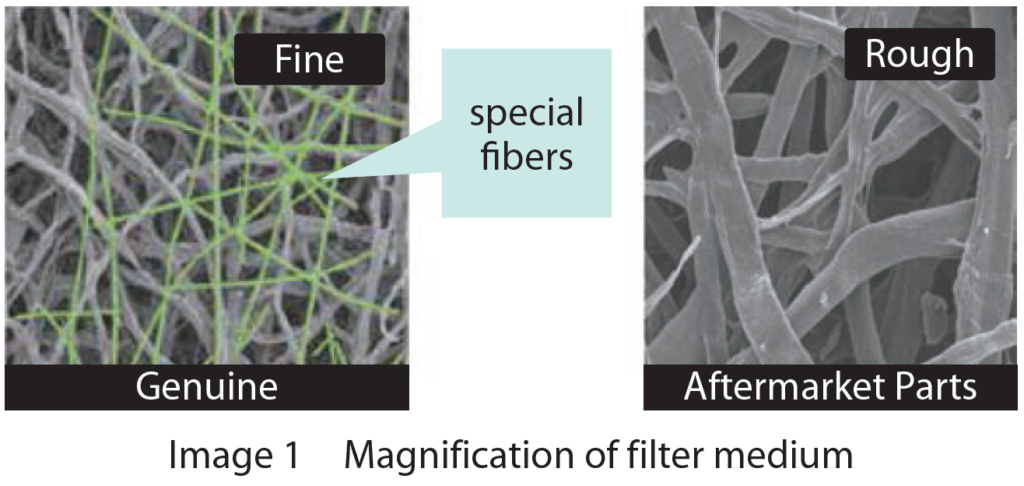

5. The importance of replacement

If the filter is not replaced periodically, the filter paper will become clogged with impurities. (See Image 3) the worst-case scenario, the relief valve may open, allowing contaminated oil to flow directly into the engine, resulting in significant damage. (See Fig. 5)