Trucks and buses use air brakes as their brake system. The compressed air that is sent to the brakes contains moisture from the atmosphere and lubrication oil from the compressor’s internal components. This moisture and oil can cause a variety of problems if they find their way into various components. The air dryer is responsible for removing this moisture and oil from the air.

2. Construction

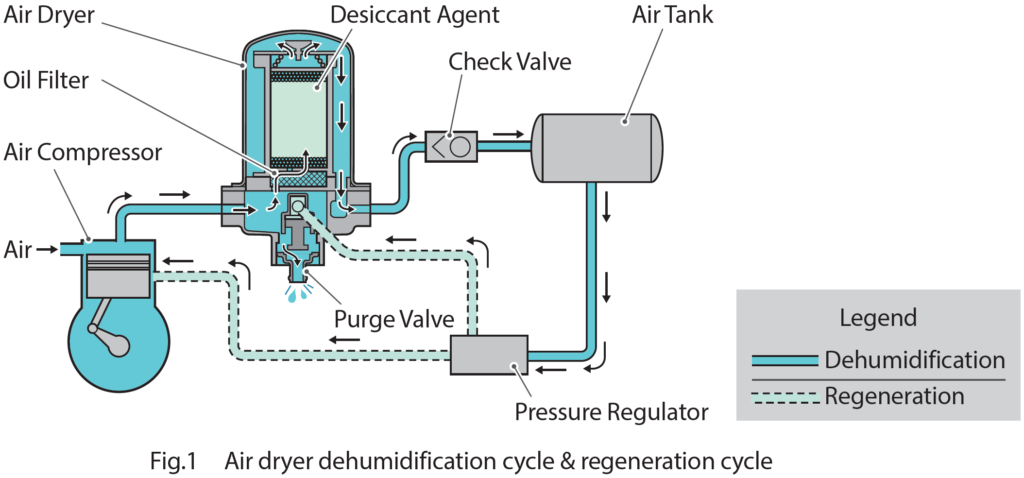

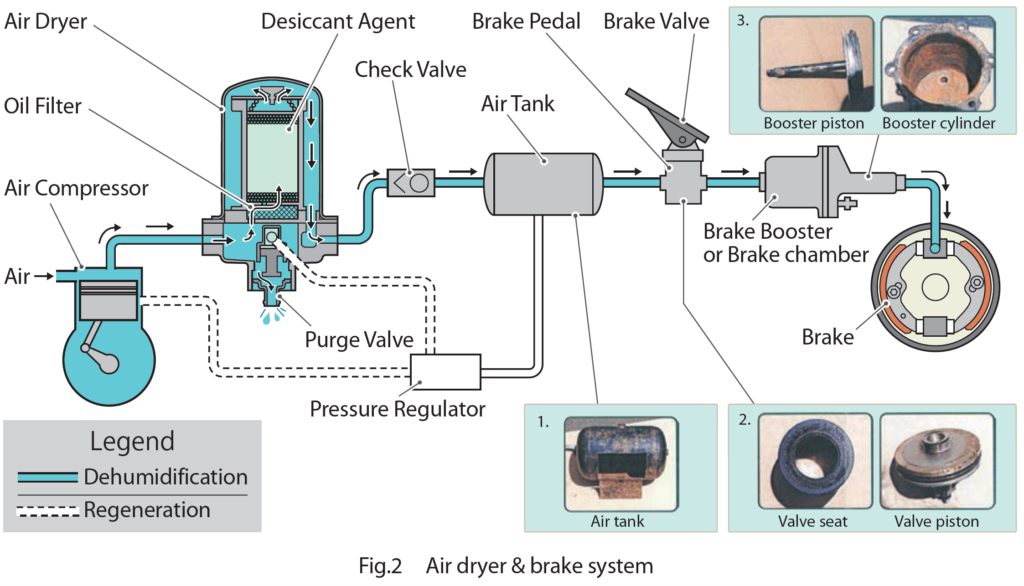

Air that is compressed at the air compressor is sent to the air dryer, which contains a desiccant that has “de-humidifying effects” to remove the moisture and oil, and send dry air into the air tank. When the brake pedal is used, the air in the air tank is sent to the brake system via the brake valve to control the brake. Furthermore, when the pressure in the air tank reaches a specified level, excess air is released by the pressure regulator, and the purge valve at the bottom of the air drier is opened to perform “regeneration,” which is a purging of the moisture and oil captured in the desiccant.

- Air compressor – This takes in air and compresses it.

- Desiccant – This adsorbs the water and oil contained in the compressed air.

- Purge valve – This is opened and the air purges the water and oil.

- Oil filter – This captures the oil from the desiccant that is purged at the purge valve.

- Check valve – This keeps the air in the air tank from back-flowing into the air dryer.

- Air tank – This is where the compressed air is stored.

- Pressure regulator – This releases the air when the pressure in the air tank reaches a specified level.

3. The importance of maintenance

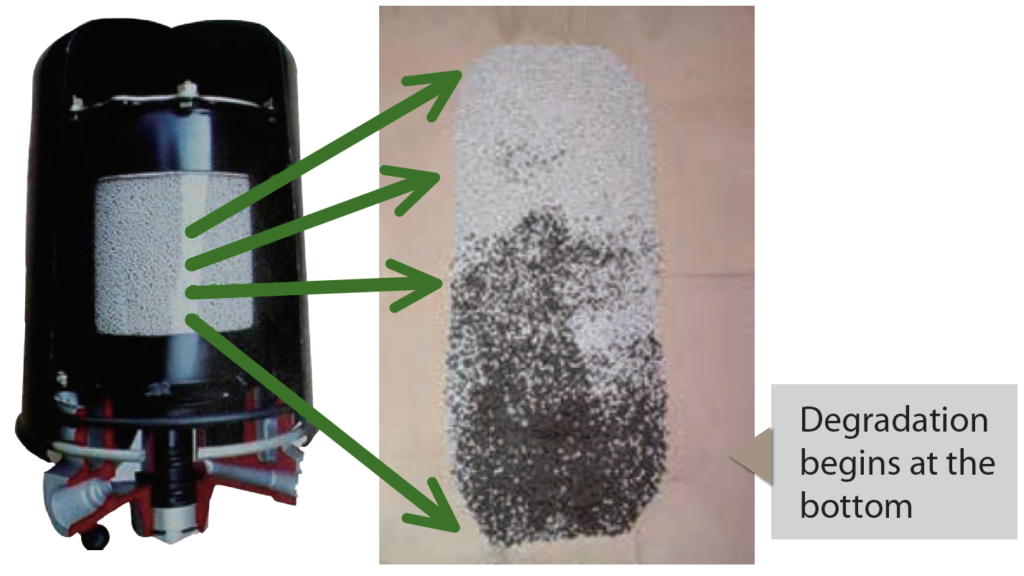

1)Aging degradation of the desiccant

The air dryer contains a desiccant to perform dehumidification. Repeated “dehumidification” and “regeneration” cycles eventually cause the oil contained in the compressed air to degrade the desiccant, gradually robbing it of its dehumidifying performance.

2) If you continue to operate your vehicle without proper maintenance. — If you continue to use degraded desiccant.

Vehicles that have not been serviced properly may experience problems with their brake systems caused by degradation or damage to the brake components. In a worst case scenario, brake components may have to be replaced, which will result in extra costs for servicing, not to mention unforeseen costs that can result from problems caused by improper servicing such as accidents or your vehicle becoming inoperable.

- Moisture and oil accumulate in the air tank, stripping the coating inside the tank. A large amount of rust is produced, and this rust is sent with the air to the brake valves.

- If rust sticks to the brake valve seat, it can cause the brake valve to stick and make your vehicle inoperable. The moisture and oil will rinse away the lubricating grease in the valve, impair valve piston movement, and consequently obstruct smooth braking.

- The moisture and oil that has escaped into the brake booster will rinse away the grease. This will cause rusting, damage to the booster’s interior, and impair braking performance.

3) The need for periodic replacement.

Desiccant degradation cannot be checked from the outside because degradation begins at the bottom, you cannot check for degradation by opening the desiccant chamber cover and visually checking it from above. As such, this is a part that must be periodically replaced.

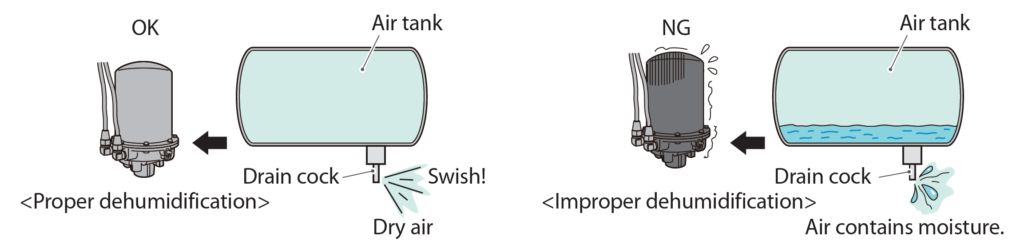

4) The need for pre-operation inspections.

When the air dryer’s dehumidification performance begins to drop, moisture will begin to accumulate in the air tank. Before you begin your day, open the drain cock at the bottom of the air tank and check to see if any moisture has accumulated (Check to see whether the dryer is dehumidifying properly). Recommend to your customers to replace the air dryer if they notice anything unusual.

<Remarks : Unit of supply>

Air dryer repair kit – This kit includes the air dryer’s desiccant, filter, O-ring and other parts that are required for making periodic replacements.