The fuel filter removes dust and moisture contained in the fuel to protect the engine’s injection pump and nozzle from wear and clogging.

How foreign matter in fuel can affect your engine:

Causes

Effects

Engine Condition

- Dust

- Moisture

- Wearing and clogging of injection pump and nozzle

- Rust

- Moisture freezes

- Loss of output

- Bad fuel economy

2. Construction

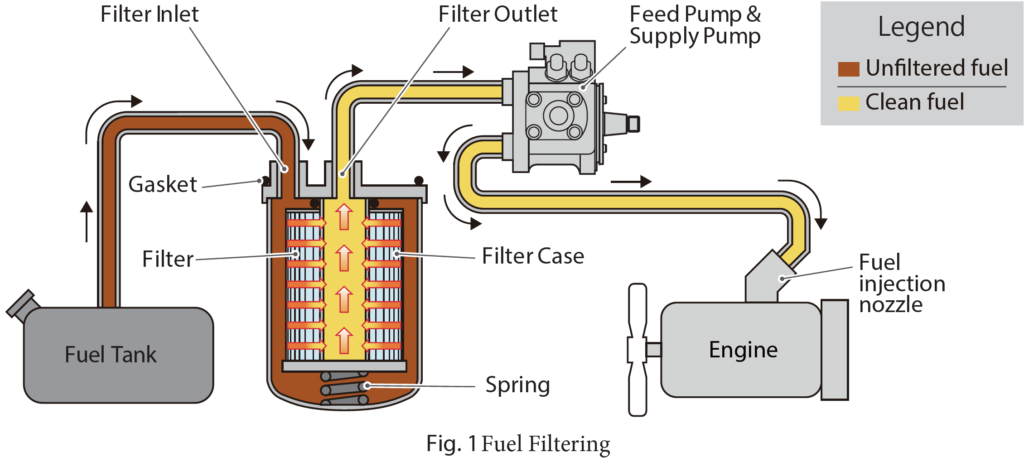

Fuel is sent from the fuel tank to the engine by suction produced at the feed pump. The fuel pump is located in this circuit. Fuel passes through the filter’s inlet, enters the filter case, and then passes through the filter medium where foreign matter is removed. (See Fig. 1)

Filter

(filter medium)

This removes dust and moisture from the fuel.

Gasket

This provides a seal to prevent fuel from leaking at the joints.

Spring

This holds the filter firmly in place in its case.

3. Filter types & features

1) There are two types of fuel filters depending on how they are attached during replacement: spin-on filters and cartridge filters.

Spin-on Filters

The filter medium is contained in a metal case which is threaded on the bottom. This type offers excellent workability as the entire case can be replaced.

Cartridge Filters

Only the filter medium is replaced, so this helps reduce the amount of waste material produced per replacement.

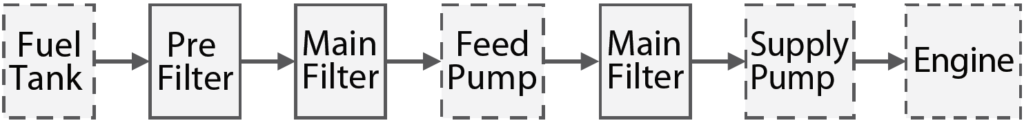

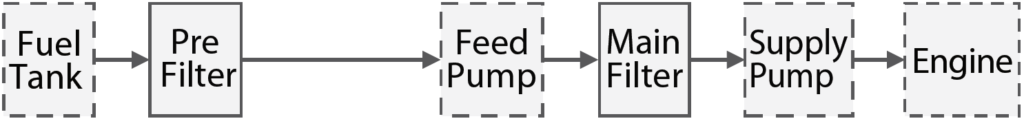

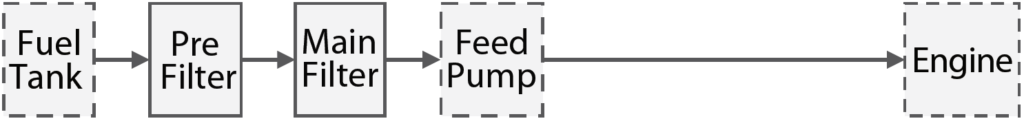

2) A main filter and pre-filter are used depending on how the fuel circuit is configured.

Main Filter

Negative Pressure

The main filter is primarily responsible for capturing fine contaminants. Negative pressure types utilize the suction pressure created by the feed pump, and are placed closer to the fuel tank than the feed pump.

Main Filter

Positive Pressure

Positive pressure filters utilize the upthrust pressure from the feed pump, and are located closer to the engine than the feed pump. Some vehicles may be equipped with both negative and positive pressure main filters.

Pre-Filter

The pre-filter removes relatively large pieces of contaminants and moisture contained in the fuel. These are installed on the circuit, close to the fuel tank.

Different types of filters are used depending on model and engine. (Typical examples)

Pre-Filter

Main Filter

Negative Pressure

Main Filter

Positive Pressure

Fuel circuit diagram

4. Differences between genuine and aftermarket parts

1. Performance

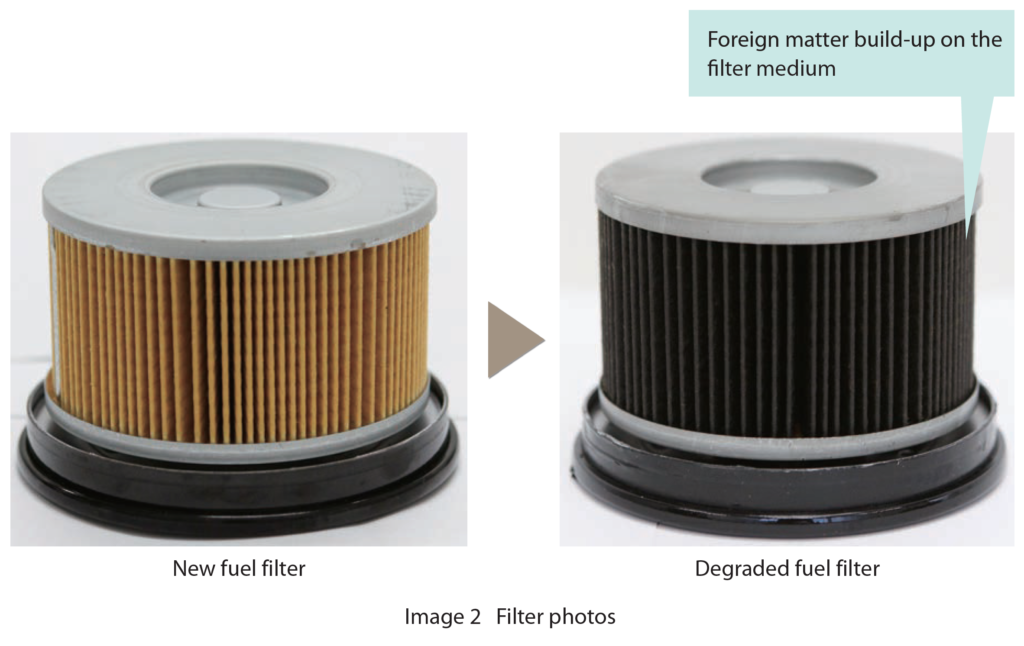

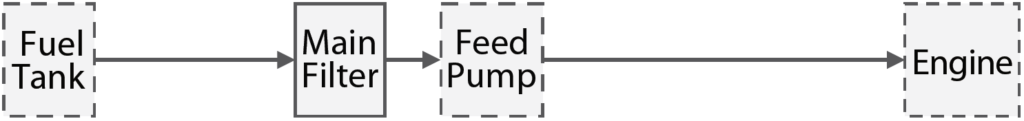

Genuine parts use special filter media that has been developed specifically for filtering fuel and offer excellent filtering performance. Some aftermarket parts use filter media with limited filtering performance. (See Fig. 2)

2. Quality

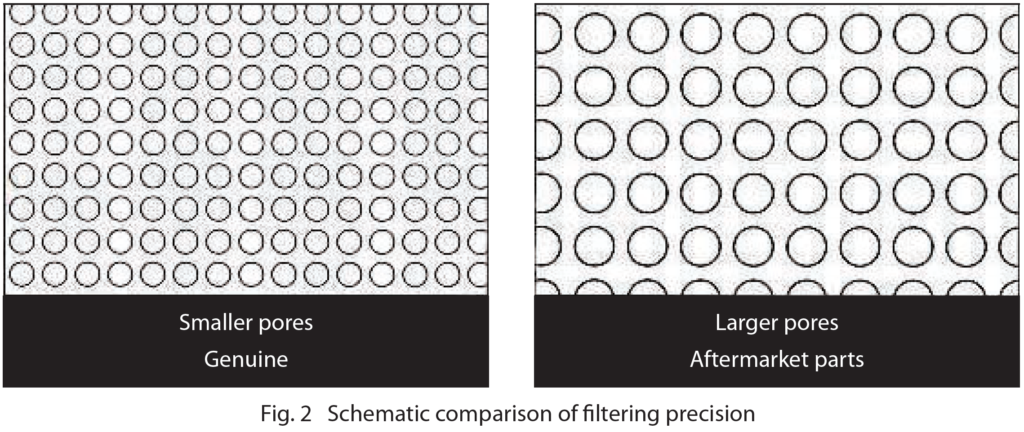

Moisture precipitation that accumulates at the bottom of a fuel filter’s case can cause the case to rust. The filter case of genuine parts have interior surfaces that are treated with a special antirust coating to keep the case from rusting and prevent consequent fuel leaks. Some aftermarket parts have not been given anti-rust treatment. This can cause the case to rust, which can eventually develop into holes, causing fuel leaks. (See Image 1)

3. Life Cycle

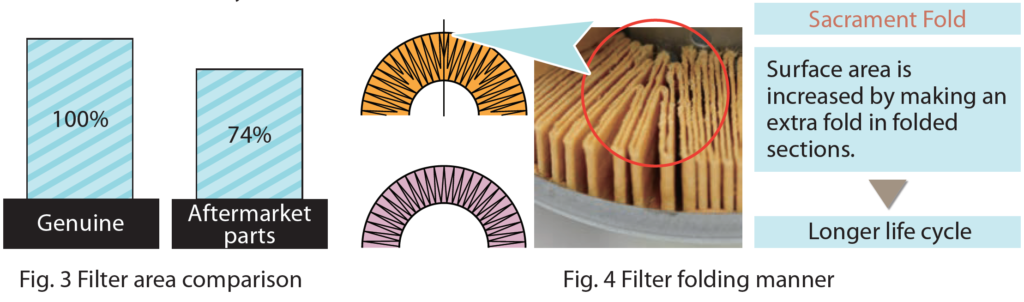

Genuine parts use filter media with sacrament fold in order to achieve finer folds and larger filtering areas that more than meet Hino’s filter change mileage requirements. (See Figs. 3 and 4)

Some aftermarket parts have only about half the filtering area of genuine filters, and consequently have much shorter life cycle.

The performance data of aftermarket parts shown above were obtained from a limited sampling of parts and do not represent the performance of all aftermarket parts.

5. The importance of replacement

Fuel filters must be replaced on a regular basis. Otherwise, the filter medium can get clogged, which will deprive the engine of its fuel supply and consequently reduce its output. If used for prolonged periods of time, the filter medium can become degraded and rupture, causing foreign matter in the fuel to reach the engine and cause major damage to your engine. So make sure to replace your fuel filters periodically. (See Image 2)